Characteristics

- Form warranty:

- 2 years

- Mold material:

- PVP (polyvinylplast)

- Collection:

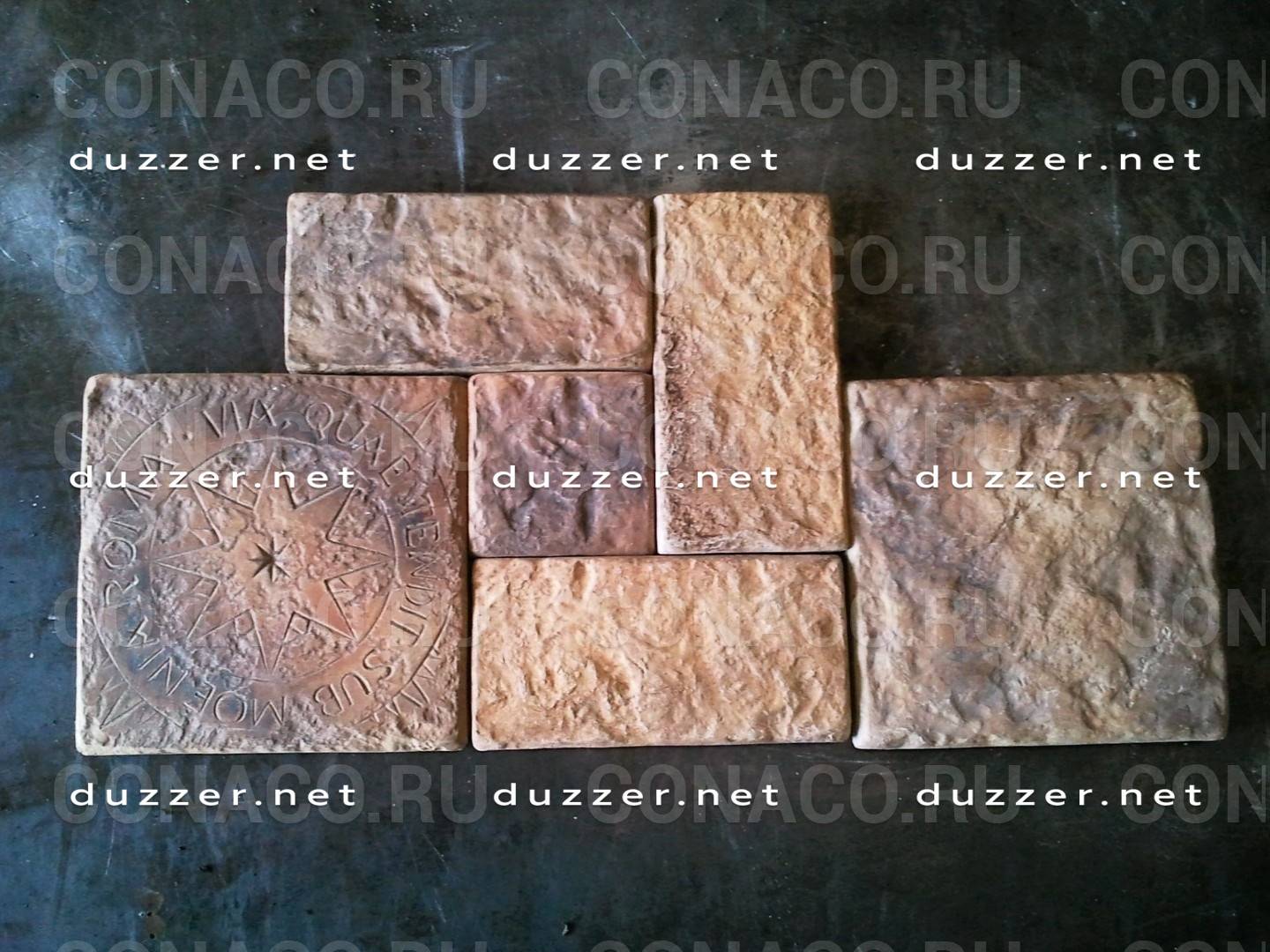

- The road to Rome

- Texture:

- cobblestone

- Tile type:

- cobblestone

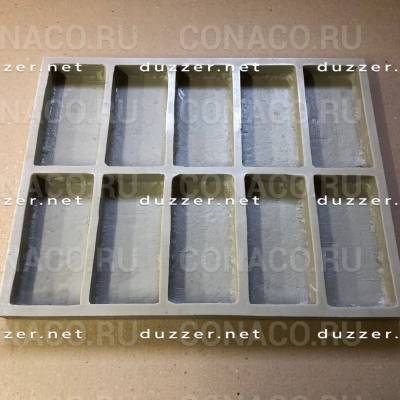

- Tile size, cm:

- 34 х 34 х 5

- Tile thickness, cm:

- 3,5

- Molded tiles area, m²:

- 0,13

- Mold size, cm:

- 14,5 х 14,5 — 4 pcs.

- Mold weight, kg:

- 4,5

Characteristics

- Brand:

- Cona

- Form warranty:

- 2 years

- Mold material:

- PVP (polyvinylplast)

- Collection:

- The road to Rome

- Texture:

- cobblestone

- Tile type:

- cobblestone

- Tile size, cm:

- 34 х 34 х 5

- Tile thickness, cm:

- 3,5

- Molded tiles area, m²:

- 0,13

- Mold size, cm:

- 14,5 х 14,5 — 4 pcs.

- Mold weight, kg:

- 4,5

In detail

You can make your own paving slabs. To cast paving slabs or paving stones, you need to buy a tile mold. Who needs these forms? First of all, to the producers of paving stones, who then sell their products. Industrial production requires long-lasting molds with geometry and texture unchanged throughout their service life. Silicone molds are best suited for this purpose. These flexible molds are like rubber molds. But they are actually made of polyurethane. Polyurethane is much better suited for casting concrete products than conventional plastic. Plastic molds for industrial production are so inconvenient that they have almost disappeared from the market.

Polyurethane molds are ideal for home use too. In personal use, the silicone paving mold is practically eternal. And all the time your paving slabs will be the same and geometrically correct.

More about the material of the form for paving slabs

We use one-component polyurethane for the production of our molds. This is the development of our laboratory. We named this new material PVP. This one-component polyurethane solves the main problem of conventional polyurethane. Before the advent of Polyvinylplast, mold makers used two-component polyurethane. This is a good material, but it has one insoluble problem: one component is washed out over time with the alkali solution. It's unavoidable. As a result, the shape changes the geometry — the paving stones are curved. And after a while, it simply breaks. And you need to re-purchase the paving slab mold.

One-component polyurethane — PVP simply does not contain this extra component. A simple solution, but we have been working towards this chemical composition for 10 years. Now the result of our research is used by thousands of manufacturers of paving stones and have actually proven the advantage of Polyvinylplast.

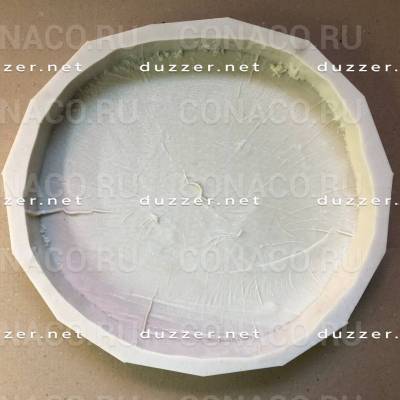

How to distinguish a polyvinyl plastic form from a two-component polyurethane product? Turn the mold over and look at its back wall. You will see small bubbles on a mold made of one-component PVC. They are inevitable, because Polyvinylplast is poured hot. Not cold like old polyurethane. By themselves, bubbles do not affect the quality of paving slabs. After all, they are on the back wall of the form, and not on the front wall. But these bubbles indicate that you have the correct, durable tile shape! It will serve you for many years and will not lose its unique properties.

Advantages of the polyviniplast mold:

- In a silicone mold, paving slabs dries 2 times faster than in a plastic mold.

- You don't need to lubricate the polyurethane mold like you did when you cast your tiles in plastic molds. The tile can be easily removed from the mold and does not stick. After all, the shape is soft and elastic.

- Cement, gypsum, resins, polymers and other materials can be poured into a polyvinyl plastic mold. The result will be consistently excellent.

- In polyurethane form, tiles can be painted in any way.

- Shore hardness — 45 A.