Characteristics

- Form warranty:

- 2 years

- Mold material:

- PVP (polyvinylplast)

- Collection:

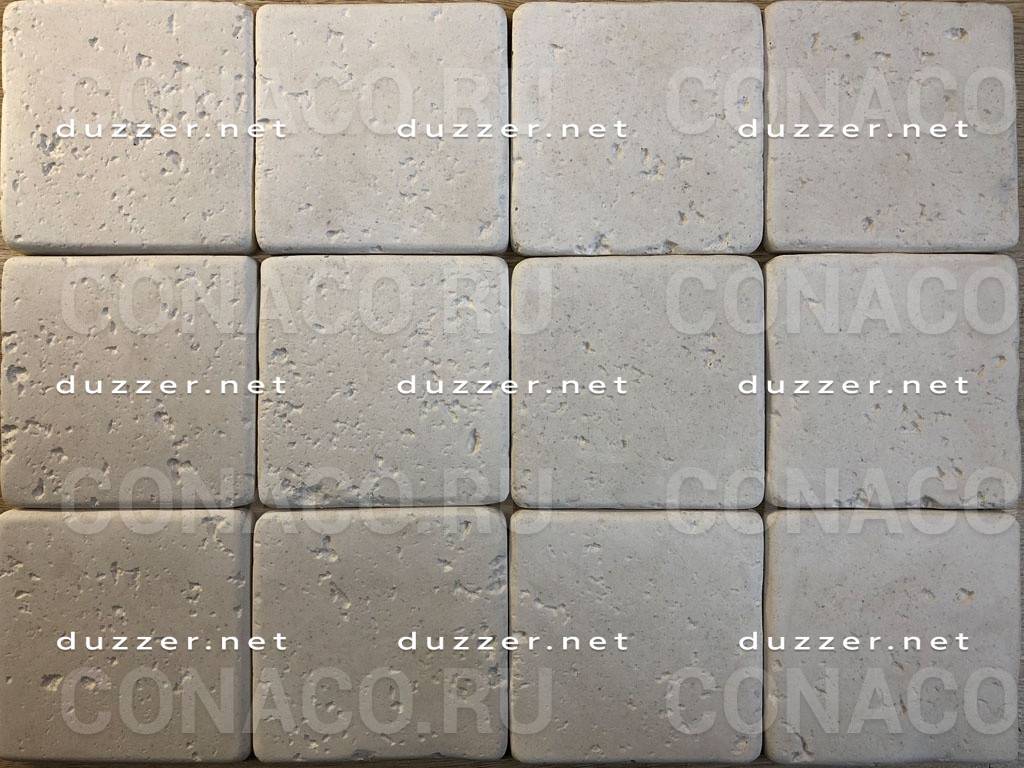

- Travertine 10x10x1 cm

- Texture:

- travertin

- Stone material:

- concrete, gypsum, resin, polymers

- Molds length cm:

- 44

- Moldst width, cm:

- 33,5

- Molds thickness, cm:

- 2

- Molds weight, kg:

- 2

- Stone size, cm:

- 10 х 10

- Stone thickness, cm:

- 1

- The number of stones in the mold, pcs:

- 12

- Effective molds area, m²:

- 0,12

Characteristics

- Brand:

- Cona

- Form warranty:

- 2 years

- Mold material:

- PVP (polyvinylplast)

- Collection:

- Travertine 10x10x1 cm

- Texture:

- travertin

- Stone material:

- concrete, gypsum, resin, polymers

- Molds length cm:

- 44

- Moldst width, cm:

- 33,5

- Molds thickness, cm:

- 2

- Molds weight, kg:

- 2

- Stone size, cm:

- 10 х 10

- Stone thickness, cm:

- 1

- The number of stones in the mold, pcs:

- 12

- Effective molds area, m²:

- 0,12

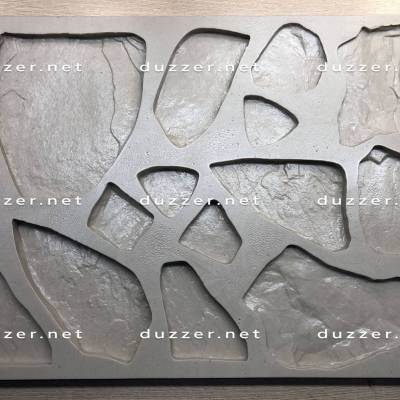

In detail

Noble and neat 10 x 10 cm travertine tiles. With our shape you will make such a beautiful stone. The most famous structure from Travertine is the Colosseum. The ancient Romans understood the meaning of beauty. They used travertine to clad their buildings and many of them have preserved their flawless appearance to this day!

We make molds for artificial stone of the highest quality. We give a guarantee for our forms. Because they are made of high quality silicone (polyurethane), which we produce ourselves. Our decorative stone molds do not wear out or tear. These molds are suitable for industrial production. Rubber stone molds are suitable for pouring concrete and plaster. Your facing stone will have ideal performance characteristics, after each pouring you will get a perfect copy of a real natural stone.

Technologies for the production of concrete stone molds:

For our molds we have developed a new wear-resistant material — one-component polyurethane. It was named PVP Polyvinylplast. The consumer properties of Polyvinylplast (one-component polyurethane) are higher than those of the old polyurethane.

Cement, gypsum, resin, polymer and other material can be poured into polyvinyl plastic molds.

The PVP mold does not need to be lubricated before pouring, the stone is easily removed from the mold after the concrete has set, because it is flexible and elastic.

Polyvinylplast molds withstands more than 3000 concrete fillings, does not break and does not lose geometry.

You can paint the stone directly in the mold — the pigment adheres perfectly to the surface.

Shore hardness 45 A.

Why we make stone molds from Polyvinylplast®

Our molds are different from those of other manufacturers. We use one-component polyurethane for their manufacture. Because one of the components is washed out of the two-component polyurethane over time. This is why bicomponent polyurethane molds lose their geometry and tear. We cast our molds from hot polyurethane. Turn our shape over and you will see small bubbles on the back surface. The bubbles do not affect the quality of the shape and the finished facing stone. There are no bubbles on the inner work surface. They are only on the back wall. The bubbles indicate that the mold was made correctly.

Polyvinyl plastic molds are durable and elastic. Outwardly, they resemble polyurethane and silicone molds. But there are significant differences in the consumer qualities of our forms: they are stronger, more flexible and are not afraid of an aggressive alkaline environment.

Molds made of polyvinyl plastic allow you to cast facing stone from cement and plaster. They do not break and serve for a long time. Polyvinylplast® better conveys the microtexture of the stone surface than molds made of polyurethane and silicone.

Service life of concrete stone mold

Our molds are suitable for large-scale production of artificial stone and for personal use at home. In production, in 24/7 mode, the mold serves for at least 5 years without deformation, breaks, does not lose geometry and does not wear out. At home, the service life is not limited.